Welcome To Neosmuk !

Product series:

Rounded (Pack of 12)

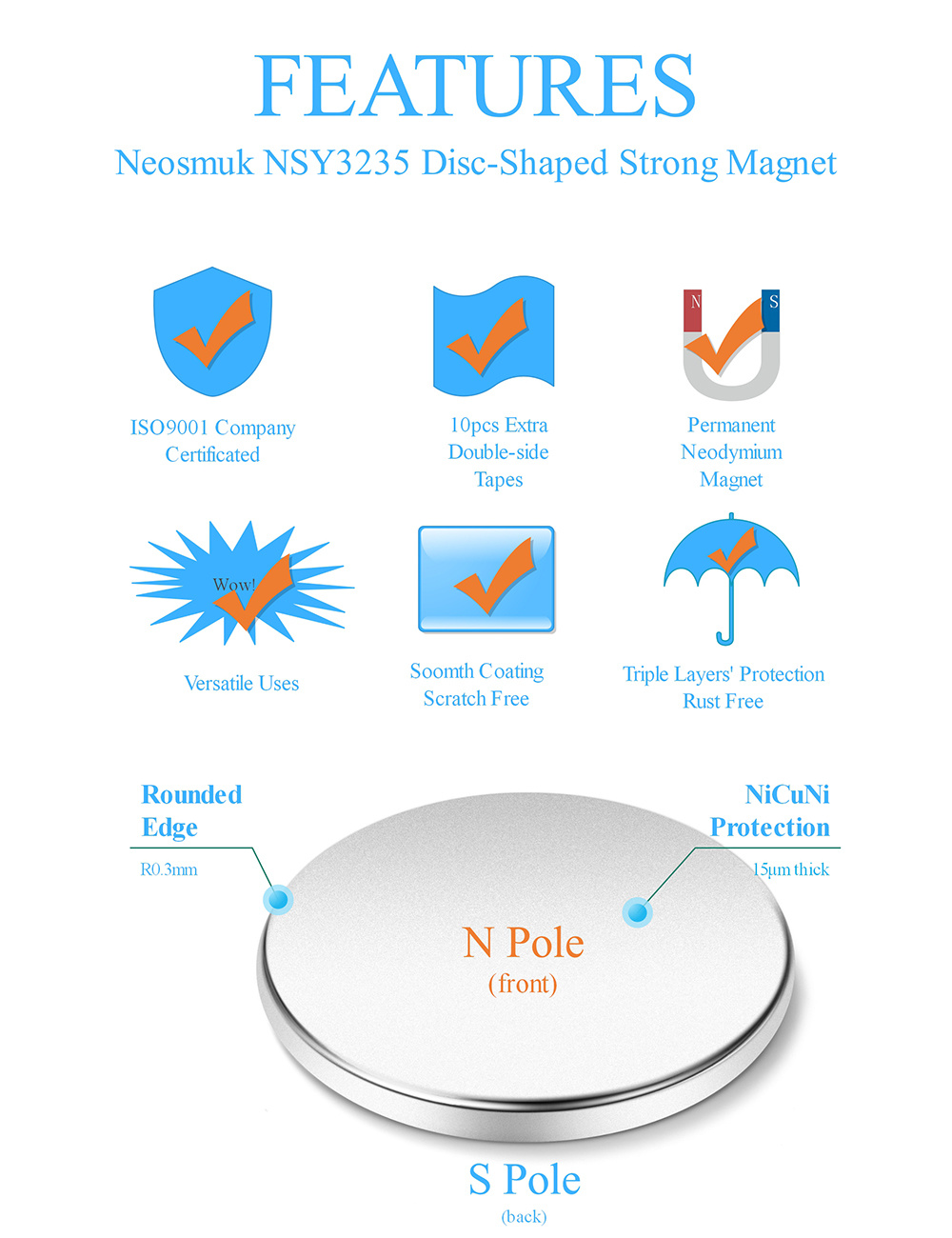

✔ SUPER POWERFUL - Amazing strong, sturdy, and reliable industrial-grade magnet, made from Neosmuk’s state-of-the-art powder metallurgy technologies, it strongly attracts any items made of ferromagnetic materials. ✔ HIGH-LEVEL PLATING - Neosmuk's nickel-copper-nickel coating plated on magnet provides s a shiny, rust-free, and mirror-like finish, It particularly exhibits an excellent anti-corrosive property and scratch-resistance and has a high washability that substantially reduces residual dust and foreign objects, along with the dimensional precision. Maintenance-free, no rust! ✔ Portable Size - Our magnet has dimensions of 1.26 inches in diameter and 0.126 inches long. Medium sizes and 10 pack quantities are ideal for carrying and use. ✔ Extra 3M Adhesive Backing - With the help of 3M backing adhesive, the application of magnet is greatly expanded. You can hang your crafts, tools... almost anywhere. ✔ Permanent Neosmuk Neodymium magnets, magnetism lasts forever!

InquiryDESCRIPTION

The Neosmuk(NS) series of magnets consists mainly of neodymium(a rare-earth element), iron and boron,and take full advantage of Neomsuk’s state-of-the-art magnetic powder metallurgy technologies.So far, a maximum energy product of 414KJ/m3(52MGOe) has been attained.

Reduce light rare earth material and avoid using heavy rare earth elements with a high risk of uneven distribution or market fluctuations, such as Nd(neodymium),Dy(dysprosium), and pioneer a new magnetic property range equivalent to or better than those of the world’s highest level high-power materials that have been achieved so far-this is an essential initiative for establishing a sustainable and stable supply system for low cost high power magnet.

Our neodymium magnet achieved the world’s highest levels of residual magnetic flux density Br, intrinsic coercive force Hcj and (BH)max. A wide variety of magnetic characteristics provides a choice of most suitable type, enabling drastic down-sizing, slimming, and increased power of magnet applied devices.

As a manufacturer providing abundant know-how on magnetic circuit designs as well as high-quality, high performance magnets, we positively support the acceleration and optimization of product designs using magnets.

Surface treatment

Ni plating features an excellent uniform electrodeposition properity, and has a high washability that substantially reduces residual dust and foreigh objects, along with the high dimensional precision. It also features high enviromental performance, covering a wide range of applicationss, from office to household and factory equipment. It particually exhibits an excellent anti-corrosive property and scratch-resistance.

Precautions

-When bonding a magnet with backing tape, pay attention so that no oil, dirt or other foreign object adheres to the bonding surface. It may decrease the adhesive force,causing the magnet to drop off.

Storage

-Do not store magnets in places where they are exposed to rain or dust or under conditions in which moisture condensation occurs; Don’t expose to fire or places with high temperature. Surface conditions,physical properties,or magnetic properties may change if stored under such circumstances.

Warning!

It is extremely dangerous to bring a magnet close to a person possessing electronic equipment such as a pacemaker or other types of electronic medical equipment. It may impair normal operations of the equipment and lead to a fatal accident

In the normal conditions, this magnet is too large to swallow. But you must be careful not to swallow cracked pieces. If cracked pieces are swallowed, consult a doctor immediately.Keep the product out of children.

Keep magnets always from magnetic recording media such as floppy disks, magnetic digital cards, magnetic tapes, prepaid card. If it is placed near to a magnetic recording medium, recorded information may be destroyed.

Property Of Neosmuk Sintered NdFeB

| Property | Remanence | Coercivity | Intrinsic Coercivity | Maximum Magnetic Energy | Work Temp. | ||||||||||||

| Br | Hcb | force,Hcj | (BH)max | ||||||||||||||

| No | Unit | KGs | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/m3 | B/μ | |||||||

| Grade | Nom. | Min. | Nom. | Min. | Nom. | Min. | Nom. | Min. | Nom. | Min. | Nom. | Min. | ℃ | ||||

| 1 | N30 | 11.2 | 10.8 | 1.12 | 1.08 | 10.5 | 10 | 836 | 796 | ≥12 | ≥955 | 30 | 28 | 239 | 223 | ≤80 | |

| 2 | N35 | 12 | 11.7 | 1.22 | 1.17 | 11.5 | 10.8 | 915 | 860 | ≥12 | ≥955 | 35 | 33 | 279 | 263 | ≤80 | |

| 3 | N38 | 12.7 | 12.3 | 1.27 | 1.23 | 11.5 | 11.3 | 915 | 900 | ≥12 | ≥955 | 38 | 36 | 303 | 287 | ≤80 | |

| 4 | N40 | 12.9 | 12.7 | 1.29 | 1.27 | 11.6 | 11.4 | 924 | 908 | ≥12 | ≥955 | 40 | 38 | 318 | 303 | ≤80 | |

| 5 | N42 | 13.1 | 12.9 | 1.31 | 1.29 | 11.8 | 11.5 | 939 | 915 | ≥12 | ≥955 | 42 | 40 | 342 | 326 | ≤80 | |

| 6 | N45 | 13.6 | 13.3 | 1.36 | 1.33 | 12 | 11.6 | 955 | 924 | ≥12 | ≥955 | 45 | 43 | 358 | 342 | ≤80 | |

| 7 | N48 | 14 | 13.8 | 1.4 | 1.38 | 10.8 | 10.2 | 860 | 810 | ≥11 | ≥875 | 48 | 46 | 383 | 367 | ≤80 | |

| 8 | N50 | 14.3 | 14.1 | 1.43 | 1.41 | 10.8 | 10 | 860 | 794 | ≥11 | ≥875 | 50 | 48 | 398 | 383 | ≤80 | |

| 9 | N30M | 11.2 | 10.8 | 1.12 | 1.08 | 10.5 | 10 | 836 | 794 | ≥14 | ≥1114 | 30 | 28 | 239 | 223 | ≤100 | |

| 10 | N35M | 12 | 11.7 | 1.2 | 1.17 | 11.5 | 10.9 | 915 | 868 | ≥14 | ≥1114 | 35 | 33 | 279 | 263 | ≤100 | |

| 11 | N38M | 12.6 | 12.2 | 1.26 | 1.22 | 11.8 | 11.3 | 939 | 900 | ≥14 | ≥1114 | 38 | 36 | 303 | 287 | ≤100 | |

| 12 | N40M | 12.9 | 12.6 | 1.29 | 1.26 | 12 | 11.6 | 955 | 924 | ≥14 | ≥1114 | 40 | 38 | 318 | 303 | ≤100 | |

| 13 | N42M | 13.2 | 12.9 | 1.32 | 1.29 | 12.4 | 12 | 987 | 955 | ≥14 | ≥1114 | 42 | 40 | 342 | 326 | ≤100 | |

| 14 | N45M | 13.5 | 13.3 | 1.35 | 1.33 | 12.6 | 12.2 | 1003 | 971 | ≥14 | ≥1114 | 45 | 43 | 358 | 342 | ≤100 | |

| 15 | N48M | 14 | 13.8 | 1.4 | 1.38 | 13.3 | 12.9 | 1059 | 1027 | ≥14 | ≥1114 | 48 | 46 | 383 | 367 | ≤100 | |

| 16 | N30H | 11.2 | 10.8 | 1.12 | 1.08 | 10.5 | 10 | 836 | 794 | ≥17 | ≥1353 | 30 | 28 | 239 | 223 | ≤120 | |

| 17 | N33H | 11.7 | 11.4 | 1.17 | 1.14 | 11 | 10.5 | 876 | 836 | ≥17 | ≥1353 | 33 | 31 | 263 | 247 | ≤120 | |

| 18 | N35H | 12 | 11.7 | 1.2 | 1.17 | 11.5 | 10.9 | 915 | 868 | ≥17 | ≥1353 | 35 | 33 | 279 | 263 | ≤120 | |

| 19 | N38H | 12.6 | 12.2 | 1.26 | 1.22 | 11.8 | 11.3 | 939 | 900 | ≥17 | ≥1353 | 38 | 36 | 303 | 287 | ≤120 | |

| 20 | N40H | 12.8 | 12.6 | 1.28 | 1.26 | 12 | 11.6 | 955 | 924 | ≥17 | ≥1353 | 40 | 38 | 318 | 303 | ≤120 | |

| 21 | N42H | 13 | 12.8 | 1.3 | 1.28 | 12.4 | 12 | 987 | 955 | ≥17 | ≥1353 | 42 | 40 | 342 | 326 | ≤120 | |

| 22 | N45H | 13.5 | 13.3 | 1.35 | 1.33 | 12.6 | 12.2 | 1003 | 971 | ≥17 | ≥1353 | 45 | 43 | 358 | 342 | ≤120 | |

| 23 | N30SH | 11.2 | 10.8 | 1.12 | 1.08 | 10.5 | 10.1 | 836 | 804 | ≥20 | ≥1595 | 30 | 28 | 239 | 223 | ≤150 | |

| 24 | N33SH | 11.7 | 11.4 | 1.17 | 1.14 | 11 | 10.6 | 876 | 844 | ≥20 | ≥1595 | 33 | 31 | 263 | 247 | ≤150 | |

| 25 | N35SH | 12 | 11.7 | 1.2 | 1.17 | 11.5 | 11 | 915 | 876 | ≥20 | ≥1595 | 35 | 33 | 279 | 263 | ≤150 | |

| 26 | N35SH-Ⅱ | 12 | 11.7 | 1.2 | 1.17 | 11.5 | 11 | 915 | 876 | ≥22 | ≥1751 | 35 | 33 | 279 | 263 | ≤150 | |

| 27 | N37SH | 12.3 | 12 | 1.23 | 1.2 | 11.8 | 11.3 | 939 | 900 | ≥20 | ≥1595 | 37 | 35 | 295 | 279 | ≤150 | |

| 28 | N38SH | 12.5 | 12.2 | 1.25 | 1.22 | 12 | 11.4 | 955 | 908 | ≥20 | ≥1595 | 38 | 36 | 303 | 287 | ≤150 | |

| 29 | N40SH | 12.7 | 12.5 | 1.27 | 1.25 | 12.2 | 11.8 | 971 | 939 | ≥20 | ≥1595 | 40 | 38 | 318 | 303 | ≤150 | |

| 30 | N42SH | 13 | 12.8 | 1.3 | 1.28 | 12.4 | 12 | 987 | 955 | ≥20 | ≥1595 | 42 | 40 | 342 | 326 | ≤150 | |

| 31 | N45SH | 13.5 | 13.3 | 1.35 | 1.33 | 12.6 | 12.2 | 1003 | 971 | ≥20 | ≥1595 | 45 | 43 | 358 | 342 | ≤150 | |

| 32 | N25UH | 10 | 9.6 | 1 | 0.96 | 9.6 | 9.2 | 764 | 732 | ≥25 | ≥1990 | 25 | 22 | 199 | 175 | ≤180 | |

| 33 | N28UH | 10.8 | 10.4 | 1.08 | 1.04 | 10.2 | 9.8 | 812 | 780 | ≥25 | ≥1990 | 28 | 26 | 223 | 207 | ≤180 | |

| 34 | N30UH | 11.2 | 10.8 | 1.12 | 1.08 | 10.6 | 10.1 | 844 | 804 | ≥25 | ≥1990 | 30 | 28 | 239 | 223 | ≤180 | |

| 35 | N33UH | 11.5 | 11.3 | 1.15 | 1.13 | 11 | 10.6 | 876 | 844 | ≥25 | ≥1990 | 33 | 31 | 263 | 247 | ≤180 | |

| 36 | N35UH | 11.9 | 11.7 | 1.19 | 1.17 | 11.5 | 11 | 915 | 876 | ≥25 | ≥1990 | 35 | 33 | 279 | 263 | ≤180 | |

| 37 | N38UH | 12.5 | 12.2 | 1.25 | 1.22 | 12 | 11.4 | 955 | 908 | ≥25 | ≥1990 | 38 | 36 | 303 | 287 | ≤180 | |

| 38 | N40UH | 12.7 | 12.5 | 1.27 | 1.25 | 12.2 | 11.8 | 971 | 939 | ≥25 | ≥1990 | 40 | 38 | 318 | 303 | ≤180 | |

| 39 | N42UH | 13 | 12.8 | 1.3 | 1.28 | 12.4 | 12 | 987 | 955 | ≥25 | ≥1990 | 42 | 40 | 342 | 326 | ≤180 | |

| 40 | N28EH | 10.8 | 10.4 | 1.08 | 1.04 | 10.4 | 9.8 | 811 | 780 | ≥30 | ≥2388 | 28 | 26 | 223 | 207 | ≤200 | |

| 41 | N30EH | 11.2 | 10.8 | 1.12 | 1.08 | 10.6 | 10.1 | 844 | 804 | ≥30 | ≥2388 | 30 | 28 | 239 | 223 | ≤200 | |

| 42 | N33EH | 11.5 | 11.3 | 1.15 | 1.13 | 11 | 10.6 | 876 | 844 | ≥30 | ≥2388 | 33 | 31 | 263 | 247 | ≤200 | |

| 43 | N35EH | 11.9 | 11.7 | 1.19 | 1.17 | 11.5 | 11 | 915 | 876 | ≥30 | ≥2388 | 35 | 33 | 279 | 263 | ≤200 | |

| 44 | N28AH | 10.8 | 10.4 | 1.08 | 1.04 | 10.4 | 9.8 | 811 | 780 | ≥35 | ≥2785 | 28 | 26 | 223 | 207 | ≤220 | |

| 45 | N30AH | 11.2 | 10.8 | 1.12 | 1.08 | 10.6 | 10.1 | 844 | 804 | ≥35 | ≥2785 | 30 | 28 | 239 | 223 | ≤220 | |

| 46 | N33AH | 11.5 | 11.3 | 1.15 | 1.13 | 11 | 10.6 | 876 | 844 | ≥35 | ≥2785 | 33 | 31 | 263 | 247 | ≤220 | |

| 47 | N35AH | 11.9 | 11.7 | 1.19 | 1.17 | 11.5 | 11 | 915 | 876 | ≥35 | ≥2785 | 35 | 33 | 279 | 263 | ≤220 | |

Property Of Neosmuk Bonded NdFeB Magnet

| Property | Remanence | Coercivity | Coercivity | Maximum Magnetic Energy | Production way | |||||||||||||

| Br | Hcb | Hcj | (BH)max | |||||||||||||||

| No. | Unit | kGs | mT | kGs | mT | KOe | KA/m | KOe | KA/m | KOe | KA/m | KOe | KA/m | MGOe | KJ/m3 | MGOe | KJ/m3 | |

| Grade | Min | Min | Max. | Max. | Min | Min | Max. | Max. | Min | Min | Max. | Max. | Min | Min | Max. | Max. | ||

| 1 | NBM19 | 8.80 | 880 | 9.3 | 930 | 6.5 | 517 | 7.1 | 565 | 11.0 | 875 | 13.0 | 1035 | 17 | 135 | 19 | 151 | Anisotropic Bonded NdFeB |

| 2 | NBM19e | 9.5 | 950 | 10.0 | 1000 | 6.5 | 517 | 7.1 | 565 | 11.0 | 875 | 13.0 | 1035 | 17 | 135 | 19 | 151 | |

| 3 | NBM23 | 10.0 | 1000 | 10.5 | 1500 | 7.0 | 557 | 7.9 | 629 | 11.5 | 915 | 13.0 | 1035 | 19 | 151 | 23 | 183 | |

| 5 | NBM12.5 | 7.40 | 740 | 7.70 | 770 | 5.6 | 450 | 6.3 | 500 | 11.0 | 880 | 12.5 | 1000 | 11.0 | 88 | 12.5 | 100 | |

| 6 | NBM11.5 | 7.30 | 730 | 7.6 | 760 | 6.1 | 490 | 6.9 | 550 | 12.5 | 1000 | 13.0 | 1040 | 10.5 | 84 | 12 | 92 | |

| 7 | NBM8.5 | 5.7 | 570 | 6.4 | 640 | 4.5 | 360 | 5.5 | 440 | 8.0 | 640 | 10.0 | 800 | 7 | 56 | 9 | 68 | Isotropic bonded Nd |

| 8 | NBM9 | 5.8 | 580 | 6.5 | 650 | 4.9 | 390 | 5.7 | 454 | 13 | 1040 | 17.0 | 1360 | 7.5 | 60 | 9 | 72 | |

| 9 | NBM9e | 5.8 | 580 | 6.5 | 650 | 4.9 | 390 | 5.7 | 454 | 11.0 | 880 | 14.0 | 1120 | 7.5 | 60 | 9.0 | 72 | |

| 10 | NBM9s | 6.20 | 620 | 6.8 | 680 | 5 | 400 | 6.0 | 480 | 8.0 | 640 | 10.0 | 800 | 8 | 64 | 9 | 72 | |

| 11 | NBM10.5 | 6.8 | 680 | 7.1 | 710 | 5 | 400 | 6.0 | 480 | 8.0 | 640 | 10.0 | 800 | 9 | 76 | 11 | 84 | |

| 12 | NBM11.5 | 7.0 | 700 | 7.3 | 730 | 5.4 | 430 | 6.1 | 485 | 9 | 720 | 11.0 | 880 | 10 | 80 | 11 | 88 | |

| 13 | NBM12.5 | 7.2 | 720 | 7.7 | 770 | 5.7 | 454 | 6.4 | 509 | 9.0 | 720 | 11.0 | 880 | 11.0 | 88 | 12.5 | 100 | |

Keyword:

Rubber Covered Magnets

Countersunk Hole Magnets

Neodymium Magnet

Magnetic Push Pins

Magnetic Knife Holder

Magnetic hook

Fishing magnet

Recommended Products